Partial stroke testing is a maintenance and testing technique used in industries that involve safety-critical devices.

It involves intentionally moving a valve or actuator only partially from its fully closed or fully open position to verify its functionality without fully interrupting the process or system it controls.

This story is part of an ongoing series on Saudi Aramco technologies that are being commercialized by Aramco’s licensing arm, Saudi Aramco Technologies Company.

|

Pre-Installation |

|

1.Plant to evaluate and decide if ZV can be completely isolated or its position can be held in place using the ZV hand-wheel 2.Air Supply must be shut down before the removal or installation of any component. |

|

Installation |

|

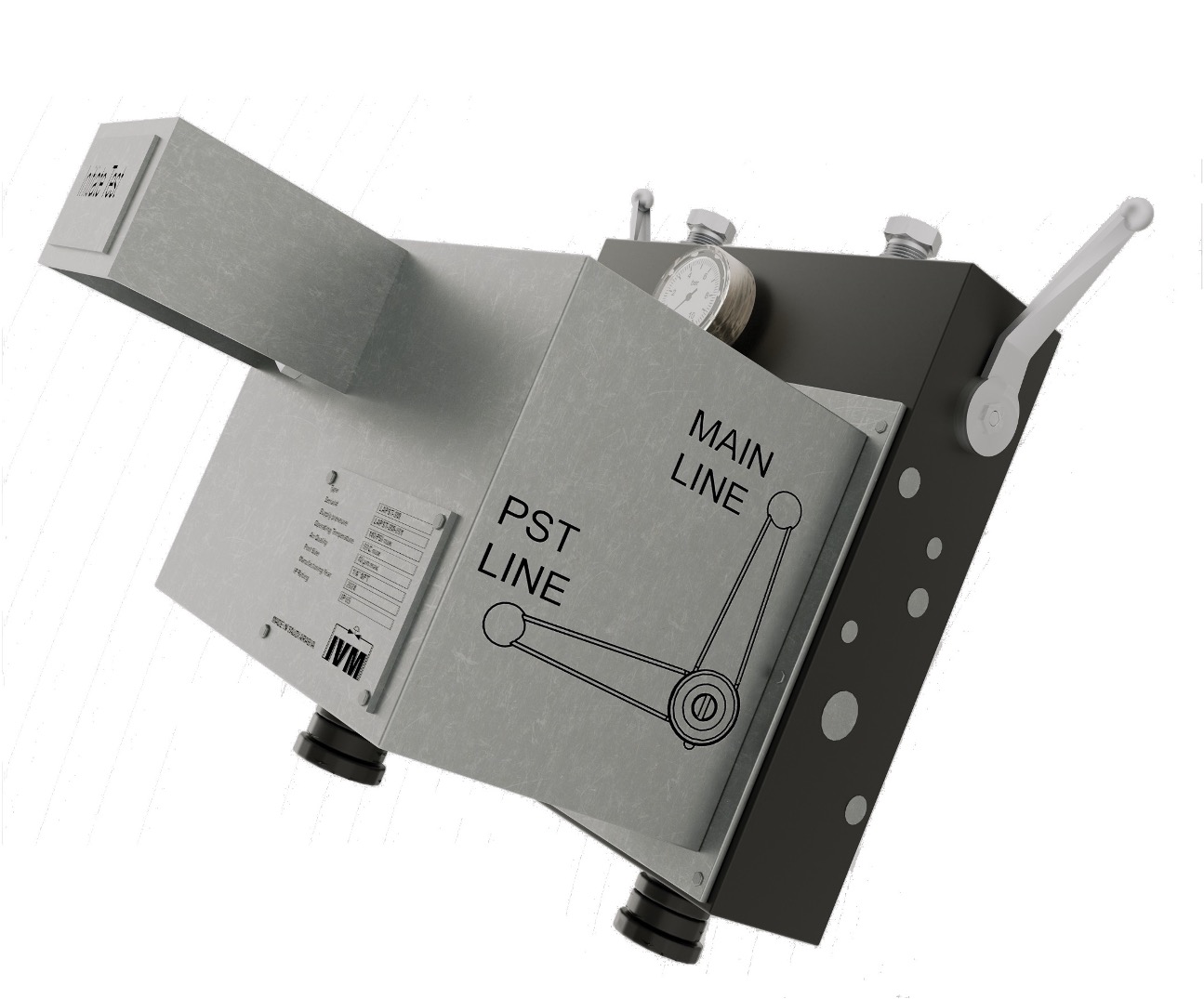

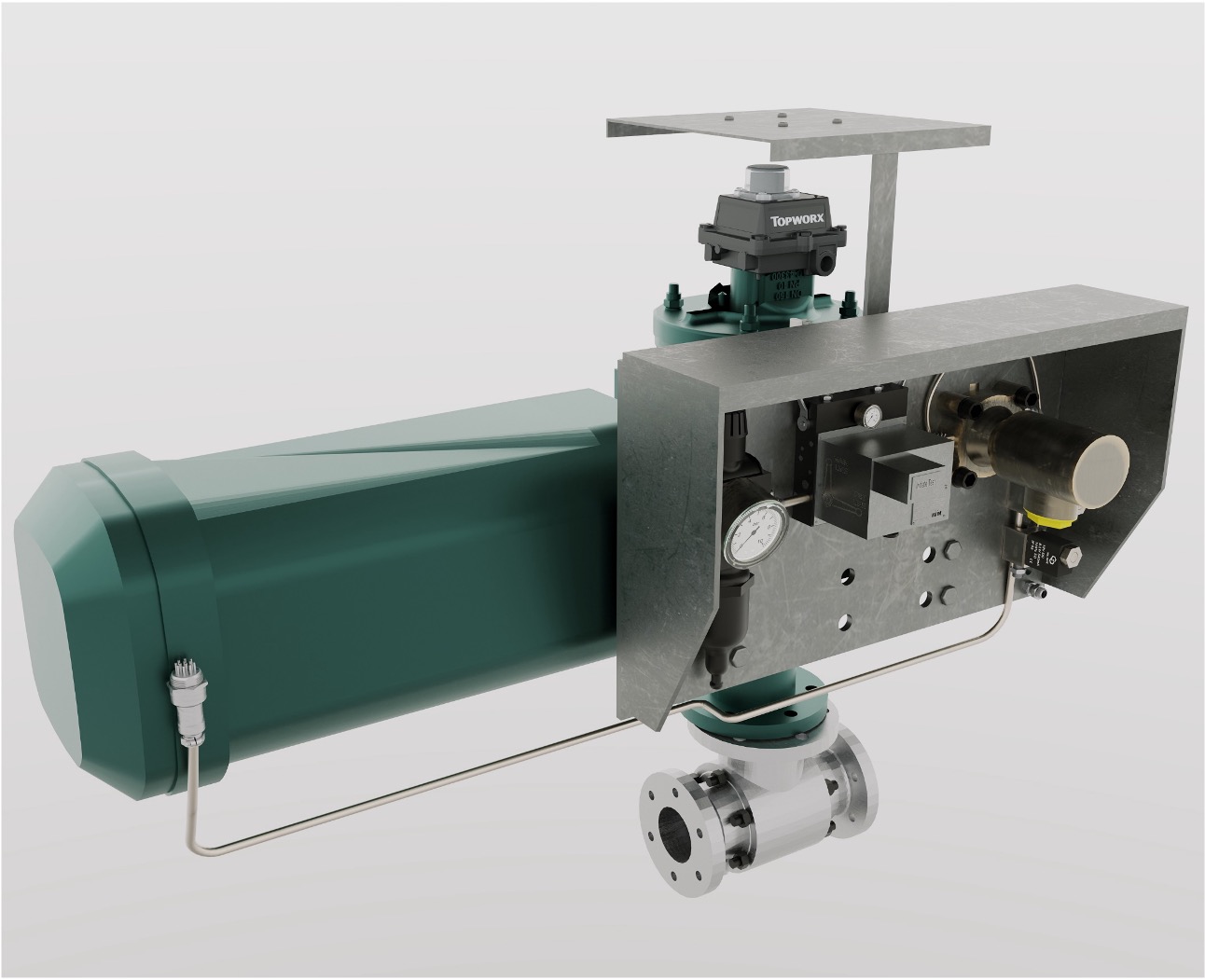

1.Bolt the LAPST device to the actuator panel while ensuring accessibility and visibility of the position indicator 2.Tubing between the air regulator and the “Supply Port” of the LAPST device and between the solenoid valve and the “Actuator Port” of the LAPST device is to be installed. 3.Once the tubing is installed, restore the air supply and check for any air leaks. If no leaks are present then the valve can be returned to normal operation. |

|

Calibration – to be performed by IVM during retrofit |

Switch from the isolation line to the partial stroke testing line by turning the levers on the isolation valves.

Hold down the push button to begin the partial stroke test. As the push button is engaged, the valve will slowly turn until the predefined testing point is reached. Once the operator disengages the push button, the valve will return to its normal position.

Once the test is complete, the operator can switch back to the main line to fully bypass the PST device, as an additional safety contingency.

Setup, calibration and testing time can be drastically reduced

• Reduced training requirements

• Setup and calibration can be simplified

• Testing will be easier to perform

• Device itself will cost less than the traditional technologies

• No additional connections, external communicators, and specialized programs

• PST using LAPST System is much simpler to perform

Time taken to install and commission ZVs can be drastically reduced with the new LAPST system

• Eliminate all wiring, cabling, LCPs, 1/0 cards, programs for PST

• Documentation, drawings, manuals are

Reduced man hours, installation and commissioning requirements, and engineering result in much lower costs

LAPST device costs are cheaper than traditional technologies

No associated equipment (LCP, 1/0 cards, cables, wiring, etc.)

No passive air or energy consumption

Reduced maintenance requirements

Simpler setup, calibration, and operation

Zero risk of nuisance trips and zero interference with SIS

No passive air or energy consumption, zero emissions

Longer lifetime, better compatibility